Skid and Package

SKID MOUNTED UNITS

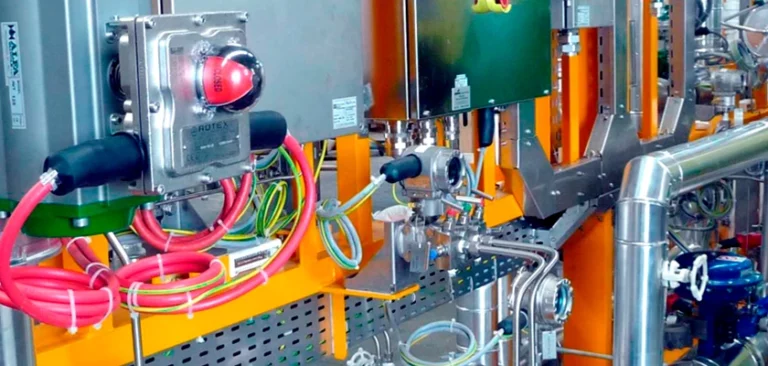

With our skilled personnel and extensive experience, our Skid & Package unit excels in providing turn-key system utilities for various sectors, including Oil & Gas (Upstream and Downstream, Offshore and Onshore), Petrochemical, Chemical, and Power plants.

WE OFFER A RANGE OF SKID-MOUNTED UNITS, INCLUDING:

Fuel Gas & Fuel Oil Skid Systems

Oil & Gas Fiscal Metering Systems

Three Phase Separator/ Separation Unit

Reduction Skid

Water Bath Heater

Oil and Gas Oil Filtration Skid

Instrument Air Production and Drying Units

Flare Ignition Systems

Ball Prover, Piston Prover

Pig / Launcher Receiver Skid

WE OFFER A RANGE OF SKID-MOUNTED UNITS, INCLUDING:

Wellhead Control Panels

Local Panels for the Control of Actuated

Valves Flue Gas Control Unit

Instrument air Distribution

CABINS AND PACKAGES

- Control and Technical Rooms Mimic Panels

Electrical Sub-Stations

Ignition and Detection Flare Systems Junction Box Rack Mounted

Pumps and Fan Control Unit Fuel Gas/Oil Skid Local Panel

Aviation Warning Light for Stack

PROCESS ANALYZER PACKAGE SYSTEMS

We excel in selecting the most suitable Process Analyzers for specific applications, whether based on client vendor lists or our own expertise. Our capabilities include supplying various Process Analyzers, such as Gas Chromatographs (single or multi- streams), Flue Gas Analyzers (O2, SOx, NOx, SO2, etc.), Moisture Analyzers, H2S Analyzers, Total Sulphur Analyzers, Density Meters, TOC Analyzers, Specific Analyzers for Natural Gas Applications (micro-GC, H2O/HC dew point, etc.), Oxygen Analyzers, pH and Conductivity Meters.

Additionally, we provide services for the design and construction of Pressure Reducing Stations (PRS), Sample Conditioning Systems (SCS), fast-loop circuits, Sample Transport Systems (STS), and the engineering and integration of AMADAS (Analyzers Management and Data Acquisition System).

ANALYZER SHELTERS & LOCAL CABINETS

We offer the fabrication and assembly of Analyzer Shelters and Local Cabinets, complete with HVAC systems, pressurization, ventilation units, lighting, wiring, cabling, piping, tubing, signal junction boxes, safety systems, and various accessories (MCT, modular unistruct, removable overhangs, etc.).

Products list

Design, Procurement, Fabrication, Workshop Testing, Technical assistance for site activities for Liquid Hydrocarbon and Natural Gas Metering System:

SYSTEMS EQUIPPED WITH Liquid hydrocarbon N. 2 PD meter 3” 150# each one designed for 100% of the max. Flow Natural gas with N. 2 orifice meter 6” 300# each one designed for 100% of the max.

Flow METERING SYSTEM DESIGNED FOR Liquid hydrocarbon – max. flow 22,00 mc/h @ the design pressure of 12 bar. Natural gas – 29.950,00 mc/h @ design pressure of 26 bar.

Design, Procurement, Fabrication, workshop Testing, Technical assistance for site activities for No. 2 Bi-Directional Prover:

CHARACTERISTICS

JM 010 – as follows: Fluid: Crude oil Pipe size: 24” 150#

Volume between detector: 10 mc Four ways valves: 12” 150#

JM 011 – as follows:

Fluid: Crude oil

Pipe size: 22” 150#

Volume between detector: 10 mc

Design, Procurement, Fabrication, Workshop Testing, Technical assistance for site activities for Diesel Oil Metering Systems.

CHARACTERISTICS

Diesel oil metering designed for a max. flow of 1500,00 mc/h @ design pressure of 35 bar. The system is equipped with No. 3 helical blade turbine each one designed for 50% of the max. and they are connected in series in order to test each with each other. System is delivered complete with its own control panel and supervisory control system for data acquisition and invoice reporting fully development.

Design, Procurement, Fabrication, workshop Testing, Technical assistance for site activities erection and start up for Gas and Condensate Metering Systems.

CHARACTERISTICS

No. 2 metering systems composed of:

Liquid application: No. 2 meter lines with 3” 300# UFM meter device connected to

dedicated flow computer and equipped with

PD meter as master.

Gas application: No. 2 meter lines with 12”

600# orifice meter device connected in Z configuration and to dedicated flow computer.

Both systems are provided with facilities to interface with flow computer DCS (Diagnostic Control System). System certified by NMI.

Four ways valves: 16” 150#

Design, Engineering, Fabrication, Assembly, Painting, Inspection, Testing, Validation, Supply, Documentation, Installation support, Commissioning for Fiscal Measurement of Crude Oil Lact Units type Bi-Directional Pipe Prover.

CHARACTERISTICS

No. 2 metering systems units:

Item 1: proving rate min. 60,00 mc/h, max 300,00 mc/h

Item 2: proving rate min. 30,00 mc/h, max 250,00 mc/h

Item 3: proving rate min. 50,00 mc/h, max 250,00 mc/h

Item 4: proving rate min. 30,00 mc/h, max 80,00 mc/h

Design, Engineering, Fabrication, Assembly, Painting, Inspection, Testing, Validation, Supply, Documentation, Installation support, Commissioning for Fiscal Measurement of Natural Gas.

CHARACTERISTICS

Supply, installation, commissioning and start-up of gas metering station with two ultrasonic flow meters size 3”

Design, Engineering, Fabrication, Assembly, Painting, Inspection, Testing, Validation, Supply, Documentation, Installation support, Commissioning for Pig Traps for Pumping Station.

CHARACTERISTICS

N. 6 pig traps 14” 600#

Supply of No. 1 custody transfer compensated gas metering system in compliance to AGA-3/API 14.3:

No. 1 meter run equipped with 8” 600# orifice meter and No. 1 meter run equipped with 16” 600# orifice meter.

Pakistan

Supply of No. 1 custody transfer metering system equipped with 6” 150# turbine meter.

Iraq

Supply of metering equipment including field instruments and bulk materials.

Saudi Arabia

Supply on No. 2 metering and proving systems equipped with 6” 600# ultrasonic flow meters.

Zimbabwe

Supply of No. 6 pig traps 14” 600# for a new pump station of light products pipeline.

Iraq

Supply of oil metering equipped with 4” UFM 300# and bi-directional prover.

Iraq

Supply of No. 1 prover and related control panel

Saudi Arabia

Al Hassakeh pump station updating and development of existing pumping station. Survey, designing & drawing, manufacturing, supplying, installing, testing, commissioning of equipment and material for the upgrade of nine 6KV switchgear / motor control centers.

Syria

Deir Ez Zoor supply of No. 1 filtering, metering and pressure reduction system mechanical tie- ins to the main pipeline control system upgrade.

Syria

Deir Ali FMS extension project supply of No. 1 filtering, metering and pressure reduction system mechanical tie-ins to the main pipeline control system upgrade pipeline control system upgrade.

Syria

No. 4 crude oil lack units equipped with PD meter and bi-directional prover.

Syria

Supply of meter run, instrumentation, site service, commissioning and start up, control system for No. 6 metering and proving system crude oil, condensate and LPG equipped with No. 2 turbine meter 10” 600#, 6” 600# and 4” 600#

Algeria

Supply of No. 2 ultrasonic flow meter line and control panel 30” 600# and 6” 300#

Greece

No. 1 ultrasonic flow meter 12” 300# in pay and

check configuration with existing 12” 300# turbine for condensate metering system.

Libya

No. 1 gas filtering and metering system with orifice meter 10” 600#, No. 1 condensate metering system with ultrasonic flow meter 4” 150#

Syria

No. 1 diesel fiscal metering skid for Vlore power plant, with No. 3 turbines 8” 300#

Albania

No. 2 gas meter run with orifice 6” 300# and No. 2 crude oil skid with PD meter 3” 150#

Libya

N° 20 THERMOREGULATION SKIDS FOR MERCEDS BRASIL PLANT

Mechanical and Electro – Instrumental Engineering for Skids. Skid Construction. Hydrostatic testing and supply. Supply of Commissioning Spare parts.

N° 1 LOCAL MANUAL CONTROL STATION FOR DAMPERS FOR JGC SINGAPORE

Electrical and Instrumental Engineering, Mechanical engineering, Supply and construction of Local Manual Control Station with sunshade. Supply of cable, and bulk material.

N° 7 MOTOR CONTROL STATION

Electrical engineering, Construction and supply of n° 7 Motor Control Station for Two Solar Gas Turbo Compressor Package for North Rumaila GTU.

N° 6 ACTUATOR FOR STACK DAMPERS

Electrical and Instrumental Engineering for n° 6 Actuators with FF Positioner model for stack dampers with BI&DI ’s product model J32. Construction, Pneumatic and electrical testing and supply.

N°1 FUEL GAS SKID FOR ATMOSPHERIC HEATER

Mechanical and Instrumental Engineering for Skids. Skid’s Construction and supply. Supply of bulk materials and cables. Interconnection mechanical engineering

N°5 FUEL GAS SKID FOR CCR PREHEATER FIRING SECTION

Mechanical and Instrumental Engineering for Skids. Skid’s Construction and supply. Supply of bulk materials and cables. Interconnection mechanical engineering

N°3 FUEL GAS SKID FOR NHT HEATER

Mechanical and Instrumental Engineering for Skids. Skid’s Construction and supply. Supply of bulk materials and cables. Interconnection mechanical engineering

N° 2 FUEL GAS SKID FOR FIRED HEATERS

Mechanical and Instrumental Engineering for Skids. Skid’s Construction and supply. Supply of bulk materials and cables.

LOCAL CONTROL PANEL FOR FIRED HEATER

Electrical and Instrumental Engineering, mechanical engineering, Supply and construction of Local Control Panel with Manual Loading Station for air Dumper. Supply of cable, and bulk material

FLAME DETECTOR/IGNITION SYSTEM RACK

Electical and Instrumental Engineering, mechanical engineering, Supply and construction of Flame Detection / Ignition System Rack. Supply of cable, Local Panel and bulk material

N° 2 FUEL GAS SKID FOR FIRED HEATERS

Mechanical and Instrumental Engineering for Skids. Skid’s Construction and supply. Supply of bulk materials and cables.

N° 198 PNEOMATIC PANEL FOR ACTUATED VALVES. Mechanical and Instrumental engineering, Supply and construction of Panels

MANUAL LOADING STATION DOR AIR DUMPER.

Electical and Instrumental Engineering, mechanical engineering, Supply and construction Stations. Supply of cable, and bulk material

FLAME DETECTOR/IGNITION SYSTEM RACK. Electrical and Instrumental Engineering, mechanical engineering, Supply and construction of Flame Detection / Ignition System Rack. Supply of cable, Local Panel and bulk material.

N° 1 CEMS ENCLOSED, WITH HVAC FOR O2 / NOX

Electrical and Instrumental engineering, hardware and software engineering, Construction and Supply of Analyzer Shelter.

N° 1 CEMS ENCLOSED, WITH HVAC FOR O2 / CO / NOX / SO2

Electrical and Instrumental engineering, hardware and software engineering, Construction and Supply of Analyzer Shelter.

- N°10 GAS CHROMATOGRAPHY ANALYZER

Systems electrical and instrumental engineering, Hardware and Software engineering, supply of Analyzer shelter.

N°2 GAS CHROMATOGRAPHY ANALYZER SYSTEMS

Electrical and Instrumental engineering, hardware and software engineering, and Supply of Analyzer Shelter. Supply of HVAC System.